Introduction

Vivan home decor pvt ltd. Group equipped with sheer drive for achieving perfection in every saphere. has been moving from strength to strength. since its inception in 1981 by its Founder Chairman Mr. Kapil Jain, who is now being supported by his two sons Mr. Rahul Jain and Mr. Vikram Jain along with a core team of knowledge enriched professionals across all levels. With aroound 3,000 employees, the company forms a pool of heighly dedicated and innovative and individuals looking for excellence and above-par results at all times. In a span of 26 years, the Group today has attained a turnover of rs 1250 Crores (US $ 200 Million).

Vivan Group comprises of four companies, vis-a-vis Vivan Steels Ltd (VSL). Vardhman Industries Ltd (VIL), Vivan Textiles Company Ltd (VTCL) and Vivanj Tinpale Pvt. Ltd. wherein VSL and VIL both are public listed companies and are enlisted at Bombay Stock Exchange.

Most recent and upcomin business venture of the Vivan Group is Vivan Textiles Co. ltd, an established fully integrated Terry Towel Unit with 4500 tonnes of Terry towel per annum

Our mission is to produce value added products of utmost standard for quality conscious global markets by utilizing the best available knowledge and technology.

In our pursuit for global excellence, we have an in-house Spinning Facility to achieve a consistent and competitive quality product. This platform ensures optimum quality at every process stage to yield the desirable product.

VTCL frimly believes in utilizing the best Human Resources avaible in order to achieve its mission. We are a team of more than 1000 highly skilled and dedicated employees involved in designing, developong and manufacturing.

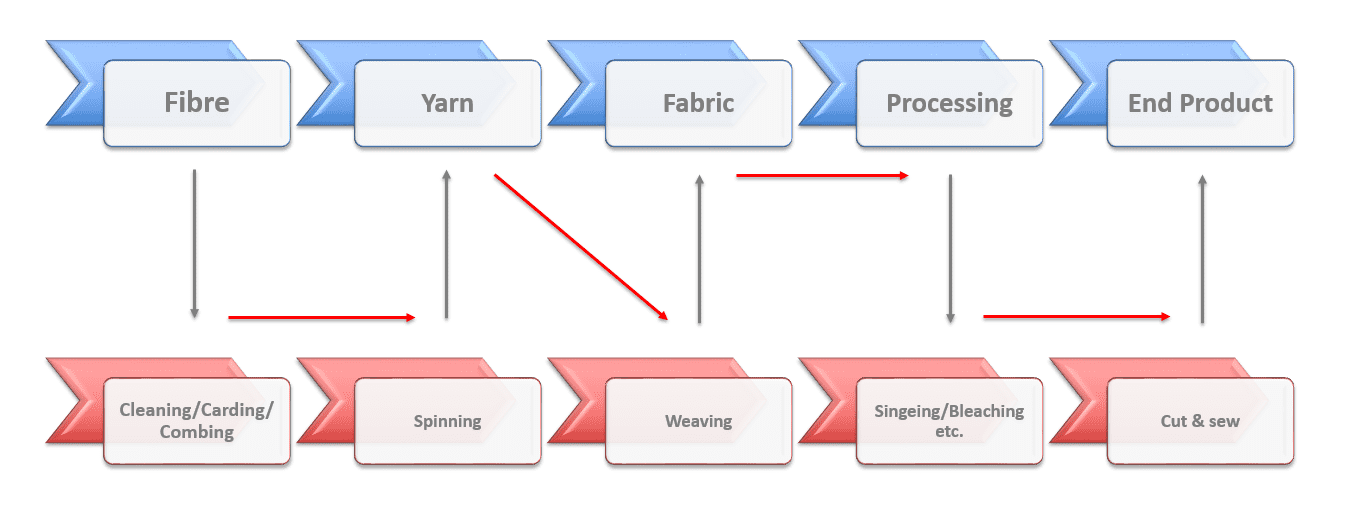

From Fibre to Finished Product

Totally integrated production invloves four main processes - Spinning, Weaving, Processing and Finishing

Spinning

The unit is equipped with a captive Spinning Mill, primarily to control quality parameters of Yarn and also for supplementing specialized yarns to the Weaving section

The strategically designed Mill has the capability to spin 3 different blends/mixings at a time.

- One line for regular production of Ring-Spun yarn (LMW)

- Another line for Open End Rotor-Spun yarn (Schlafgort).

- Third line exclusively for Organic.

Some other remarkable feature of the Mill are :

- Contamination Scanner

- Equipped to produce Compact Spun yarn (Sussen).

- Assembly Winding Machine (Peass / Schlafhorst)

- Twisting Section (Savio, Italy).

- Humidification Plant (LIWA, Switzerland).

- Advanced laboratories for minoriting and controlling the process and yarn quality parameters (Uster, Switzerland).

- Electronic yarn clearers - On Auto Coners (Uster Quantum 2) - On Rotors of Open End (Color lab XQ Digital Tech.)

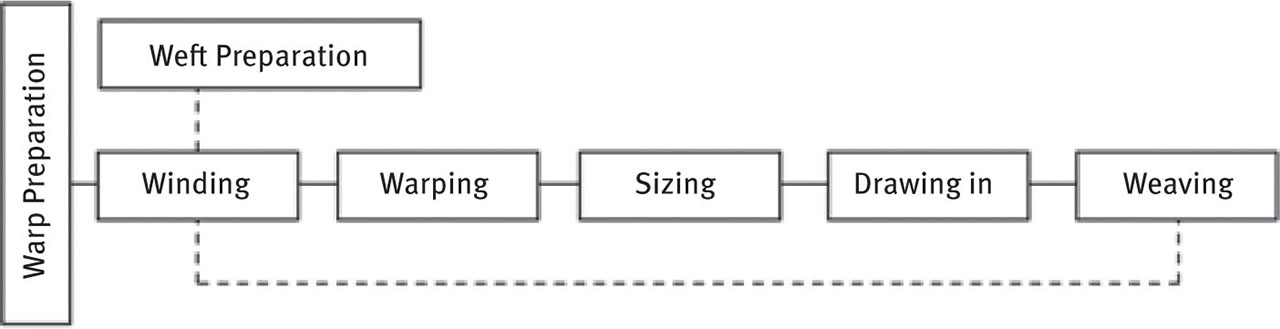

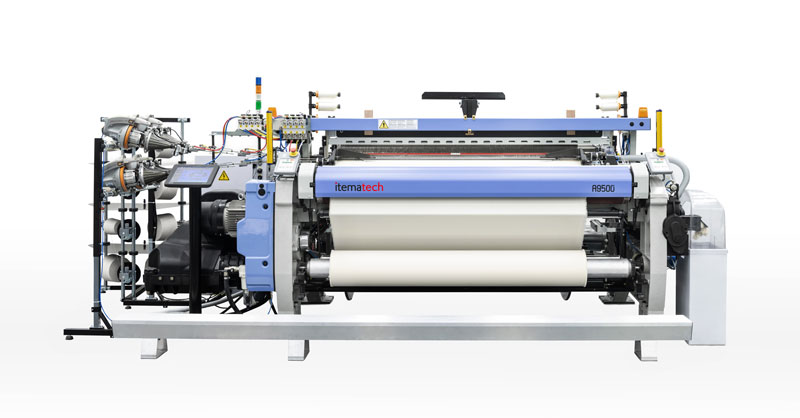

Weaving

The weaving mill presently equipped with 49 lloms (scalable up to 84 looms in the 2nd phase ) can weave everything from the simplest 2-shaft can weave everything from simple dobby weaves to acomplished jaquard patterns of ny size, quality and weight.

- 33 Air Jet Dobby Weaving machines (Tsudokama, Japan) with batching motion

- 16 Jacquard weaving machines (Donier, Germany) equipped with Boras Jaquard

- All machines incapacilated to produce 3/4 pick terry with infine variable pile heights.

- Flexibility of weaving 8 different weft densities up to 4-8 colors in the weft.

Processing

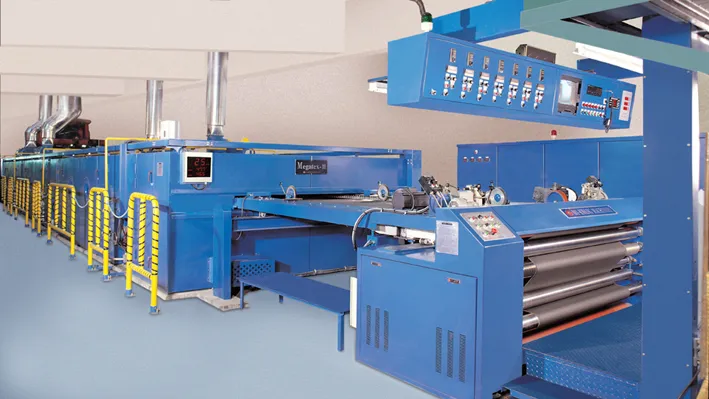

The processing unit comprises of state of the art machinery equipped with lates technology

- Soft flow machines (Brazzoli, Italy)

- Latest horizontal type Yarn Dyeing machines (Galvanin, Italy)

- Hydro extractors (Galvnin, Italy) and continous tumbler dryer (Turbang) from Anglada, Spain

- Weft straighteners (Bianco, Italy) followed by Relaxed Dryer and Stenter frame.

- Automatic dispensing systems (Color Service, Italy) to ensure homogeneitly and consistency of shades.

- Well equipped laboratory (Data Color,Us) with automatic dispensing and dyeing machines for fast shade developments

Printing

- Flat Bed Printing Machine, First of It's Kind in India

- Under one vincity, we have now all processes starting from Spinning, Weaving, Dyeing, Printing, Bathrobe, Embrroidery & packing.

- It's Fibre Reactive Piece Printing

- Better control of Shrinkage

- 3mt/Day Production Capacity

- Can Print Max. 10-12 Colours

- Effective Printing Area : 59" X 71"

Finishing

The dyed and woven fabric is by sewing, folding and customized packing

- Latest stiching machines (schmale Durate) including longitudinal cutting, longitudinal hemming(single needle and double needle)

- Automatic cross cutting machines.

- Shearing and polishing machines (Mario Costa, Italy).

- In-house embroidery machines (Barudan, Japan).

Cancellation and Refund Policy

Cancellation:

- Within 7 Days: You have the option to cancel your order within 7 days of purchase. To initiate the cancellation process.

Refund:

- Eligibility: To be eligible for a refund, the cancellation must be made within the specified 7-day window.

- Refund Process: Once your cancellation request is approved, we will process the refund to the original method of payment.

- Timeframe: Please allow 5-7 business days for the refund to be reflected in your account.

Contact Us:

If you have any questions or concerns about our cancellation and refund policy, please don't hesitate to reach out to our customer support team at Contact us.

Added to your shopping cart successfully.

Ditsy Floral Dress

Color: Gray

1 X ₹113.88